+603-9226 3753 / +6017-302 3744

enquiry@alkene.com.my

B-03-04 Pusat Komersial Southgate

Vermeer Process specializes in process filtration. As designer, trouble-shooter, manufacturer, and supplier we can advise, design, and deliver the ideal service or product throughout the course of your projects. To us, effective filtration means considering filter efficiency, redress life and price-quality ratio. Another significant consideration is decreasing maintenance costs. More attention to maintenance means less expensive shut down time. For example, by evaluating and decreasing total costs of ownership, we can make process risks transparent.

The range of products that Vermeer Process Technology designs and fabricates includes not only filters, strainers, self-cleaning filters, and flow equipment, but also specially developed one-offs. Keywords for all our products are filter efficiency, extended lifetime, price-quality ratio and decreased maintaining costs by reducing shut down time. Vermeer Process Technology has experience in working with almost any (exotic) material you can think of

Vermeer Process provides filtration solutions and services for:

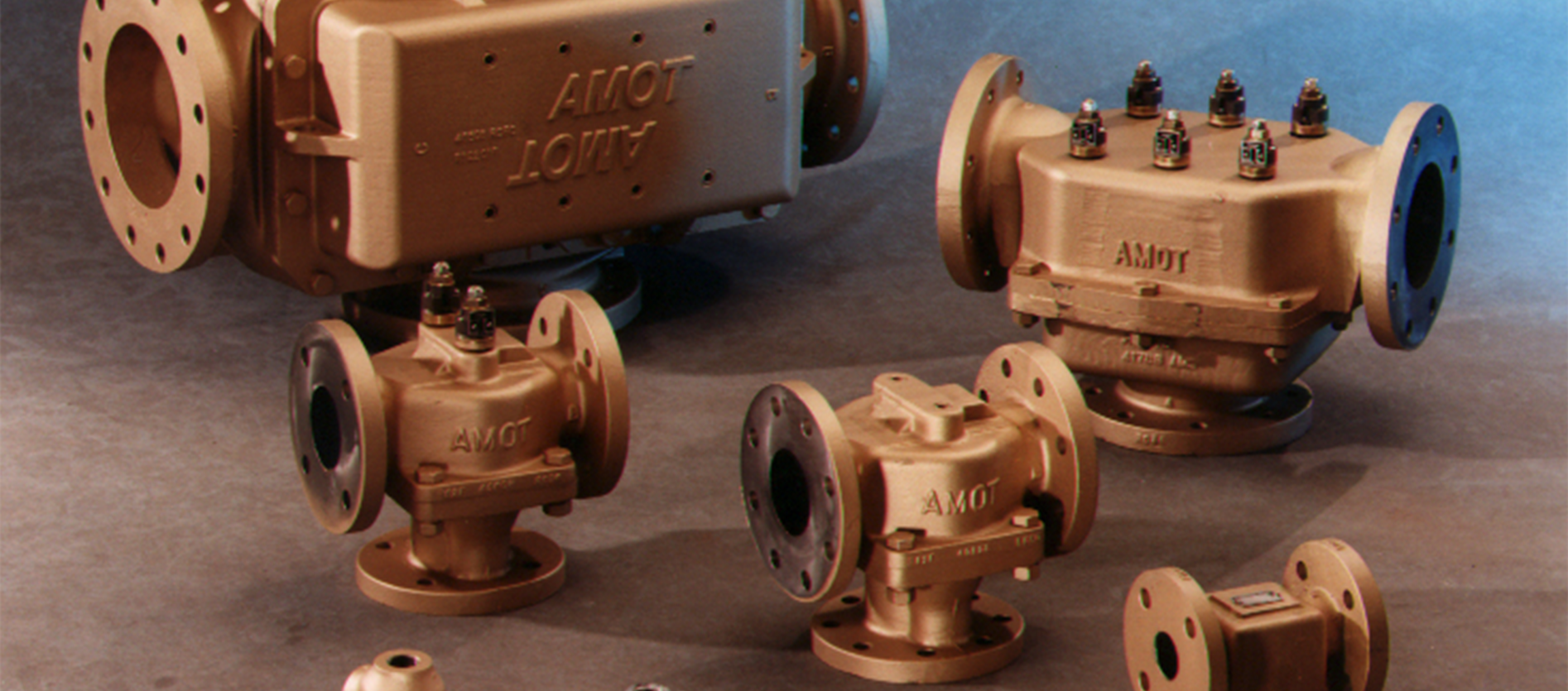

AMOT is the world’s leader of designer, developer and manufacturer of safety products and solutions for critical rotating equipment operated under hazardous area. This equipment could be ranging from engines, compressors to turbines.

AMOT’s product families include valves, electric and pneumatic instrumentation, control and condition monitoring systems and hazardous area safety products.

AMOT has control and safety solutions for a wide variety of applications, supported by its vast experience and in-depth capability including custom engineered solutions to meet specific customer requirements. We offer solutions for diesel engines, engine control and monitoring, compressors, turbines, marine, hazardous areas and many other applications.

AMOT products are extensively installed and utilized in various industries, including Oil & Gas, Power Generation, Marine, Transportation, Mining, and many others.

Procedyne Engineers, synonymous with strainers, an integral component of any process system. Strainer filters are an economical insurance policy protecting valuable pieces of equipment like pumps, heat exchangers and flow meters from potentially damaging particles. Procedyne strainers are used extensively throughout the steel, chemical, power, oil, paper, and wastewater treatment industries. Procedyne boasts of over 50,000 installations of strainers. These numerous installations stand testimony to the performance of our strainers and acceptance of all types of straining applications.

Procedyne could offer Y Type Strainers, Basket Strainer, Duplex Strainers, and Automatic Strainers ranging from ¼” to 24”. With the engineering capabilities, Procedyne Engineers could customize strainers to meet with your specific requirement. Body materials include Cast Iron, Cast Steel, Stainless Steel, Alloy 20, GRP/FGP and Bronze to exotic materials, such as Monel, Hastelloy, Super Duplex Stainless Steel and Titanium.

Procedyne Engineers have happy customers all over the world from oil & gas industries, petrochemical, power generation etc.

Holland Marine Services Amsterdam B.V. is the designer, producer and supplier of the smallest design Biological Sewage Treatment units, Grease Separators, Grey Water tanks, Ejector type Vacuum Toilet systems and supplier of Reverse Osmosis Fresh Water generators, UV disinfection units, Hydrophore units and the Jets Vacuum Toilet systems.

To meet the present demands and meanwhile providing flexibility in design, a new innovative line of Biological Sewage Treatment systems is developed by Holland Marine Services Amsterdam.

HMSA is supplying to shipyards and ship owners all over the world through a network of agents for all kind of projects, from Multi-Purpose Container vessels to House boats in Nigeria and from FPSO’s to Luxury Super Yachts.

A Type Approval was received from Lloyd’s Register of Shipping and The Netherlands Shipping Inspection after a comprehensive long term testing period.

Oil in Water Analytical Experts

Advanced Sensors continues to deliver step change technology for Oil in Water analyzers. We combine technologies such as fluorescence, absorbance, video microscopy with ultrasonic cleaning and optical spectrometry to ensure analyzers provide precise readings reliably and continuously. In addition, our experienced technical support team can provide advice and guidance on all your oil in water monitoring needs.

Determine Total Sulfur and Total Nitrogen in a Single

Analyzer

NSure Sulfur: ASTM D5453, D6667, ISO 20846

NSure Nitrogen: ASTM D4629, ASTM D5176, DIN 38409, TEIL

27, EN 12225

NSure is our next-generation total sulfur and total nitrogen analyzer offering reliable and repeatable measurements over a wide range, even during process swings and ensures tight correlation with primary test methods. NSure's updated technology guarantees ease of use and maintenance. This innovative process solutions for gas, LPG and liquid samples is ideal for online monitoring of blending and refinery operations, as well as petrochemical, wastewater and emissions monitoring. NSure, uses the same proven robustness of its previous model —the 6200.

The ViscoPro 2100 by PAC is the next generation viscosity transmitter for the process industry. By incorporating the oscillating piston method, an industry-proven sensor technology, the ViscoPro 2100 is the best choice for applications requiring fast, real-time analysis and reliable data that correlates tightly with laboratory results. Built using the same robust sensor technology that is installed at more than 10,000 locations worldwide, the ViscoPro 2100 delivers highly reliable, real-time viscosity data. With a small sample size, easy installation, flexible configuration, and minimal maintenance needs, the ViscoPro 2100 is the ideal viscosity transmitter for almost any refinery, petrochemical, or coatings application.

Produced Sand Sampler

Acoustic Sand Monitoring

Specializing in engineering, implementation, troubleshooting of control system solutions that are designed according to specification.